Emission Control

Emission Control

EMISSION CONTROL

Biomass burning (e.g., wood, agricultural residues, charcoal) releases particulate matter (PM), including harmful PM₂.₅ and PM₁₀, which contribute to air pollution, respiratory diseases, and climate change. Effective control of these emissions is critical for public health, environmental protection, and sustainable energy use. Source of the particulate matter are from biomass power plants, boilers.

Particle Types:

- PM₁₀: Coarse particles (e.g., ash, dust).

- PM₂.₅: Fine particles (e.g., soot, organic compounds).

- Black carbon: A climate-warming component of PM₂.₅.

Post-Combustion Technologies such Mechanical Collectors:

- Cyclones : Remove coarse particles via centrifugal force (efficiency: 50–90% for PM₁₀).

- Electrostatic Precipitators (ESP) : Charge particles and capture them on plates (90–99% efficiency for fine PM).

- Fabric Filters (Baghouses) : High-efficiency (>99%) for PM₂.₅ using porous materials.

- Wet Scrubbers : Use water or chemicals to trap particles (effective for acidic gases and PM).

- Catalytic Converters : Break down pollutants in industrial flue gases.

Controlling particulate emissions from biomass burning requires a mix of technological upgrades, policy enforcement, and community education. While challenges like cost and cultural inertia persist, innovations in filtration, combustion efficiency, and sustainable fuel alternatives offer pathways to cleaner air and climate resilience. Integrating these strategies with broader renewable energy goals ensures biomass remains a viable, low-impact energy source.

Bag filter and ESP are the most common emission control equipment in biomass application, both has its own characteristic and superiority. Some property of these two are :

Bag Filter

Bag filters are essential for controlling particulate emissions (e.g., ash, soot, and unburned carbon) from small to medium boilers, ensuring compliance with air quality regulations and protecting downstream equipment. Below is a tailored guide for integrating bag filters into boiler systems.

Some Bag filter Material

Electrostatic precipitator (ESP)

Electrostatic precipitator (ESP) is highly efficient technology for capturing fine particulate matter (PM) from flue gases in biomass boilers. They are particularly suited for large-scale systems where high-temperature, high-volume gas streams require robust emission control. Below is a detailed breakdown of their role in biomass combustion systems :

Key Advantages for Biomass Boilers

- High Efficiency : Captures 99%+ of PM, including submicron particles

- Low Pressure Drop : Minimal impact on boiler draft (<250 Pa vs. 1–2 kPa for bag filters).

- Temperature Tolerance : Operates effectively at 150–200°C

- Low Operational Costs : No filter replacements; only periodic electrode cleaning.

Design Considerations for Biomass Applications

Flue Gas Composition : Biomass combustion generates

Fine Ash : High silica content (e.g., rice husk, straw).

Alkali Salts : Potassium, sodium (corrosive at high temps).

Moisture : Up to 20% in flue gas from wet biomass.

Electrode Material

Stainless Steel : Alkali corrosion resists.

Corten Steel : For high-sulfur biomass (e.g., waste wood).

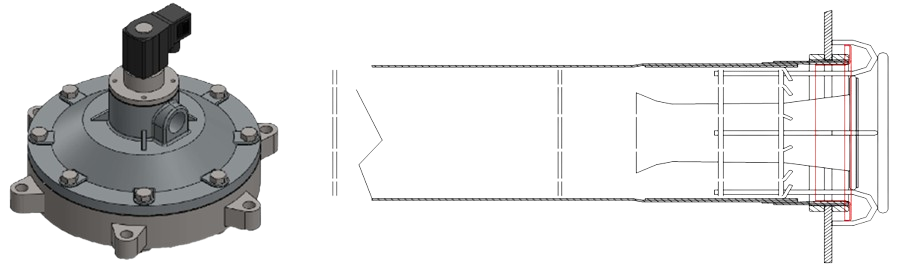

Core Spare Parts for ESP

Discharge Electrodes (Emitter Electrodes)

Collecting Plate

Rapping system

Insulator bushing